Kemet material implements the industry model of [edge banding testing standards]

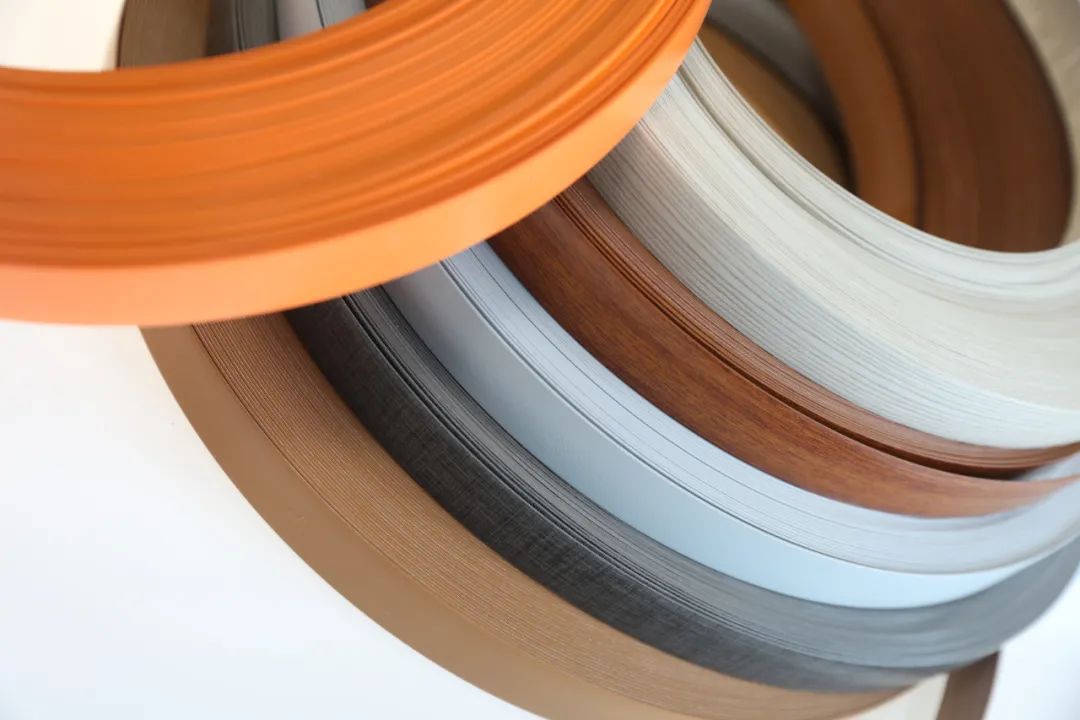

Furniture has always been the highlight of home improvement, and it is also the most expensive part, so furniture has become more and more the focus of people's home improvement. One of the important factors that determines the quality of furniture is edge sealing. The quality of the edge banding determines the service life of the furniture, as well as its aesthetics and environmental health. Strictly edge-sealed panels not only make furniture look more beautiful and feel smoother, but also can effectively control the amount of formaldehyde released in the panels, making our homes more green and environmentally friendly. The pursuit of high quality has always been the commitment of Kemet Materials to consumers. The products produced by imported raw materials and accessories, scientific formulas and advanced technology fully meet the corresponding edge banding testing standards. Some people will ask: "What is the testing standard of edge banding?" Then, in today's article, we will popularize the testing standard of our edge banding. |

How do consumers identify the quality of the edge banding?

Whether the edge is good or bad, you can actually feel it when you touch it with your hand.

The edge of high-quality furniture is delicate, smooth, and has a good feel, while the edge of inferior quality is just the opposite. Some edge-sealing strips are relatively fragile and will break when they are folded, while edge-sealing strips with good toughness are not easy to break, and can also reduce the release of formaldehyde. . Then the eye is also an intuitive method to see whether the edge is neat, whether there are bulges or roughness. Then look at the adhesiveness of the seal on the side and the glue. Particle board and MDF are glued by chips, so if the amount of glue is not enough, the seal is easy to fall off.

Of course, we can also take some measures to carry out simple detection with the sample:

1. Check whether the back of the edge banding strip is flat. You can use a flat blade to clamp the edge banding strip horizontally to see if it is straight. If it is not straight, there will be thick glue lines on both sides of the edge banding;

2. Check whether the surface of the edge banding strip is smooth and flat, and whether there are any stray spots. If there are stray spots or fine hair pinholes, it may be made of recycled PVC;

3. Whether the side of the sheet is uniform after trimming, if there is jaggedness, it may be due to the following reasons: the trimming knife is too dull; the edge band is too hard; the edge band contains too much calcium carbonate;

4. Use fingernails or other tools to scratch the edge strip. If it is damaged, the surface wear resistance and hardness of the edge strip do not meet the standards, which proves that the quality of the edge strip is unqualified;

5. Use a small piece of edge-sealing strip to seal the edge, and then tear it apart forcefully to check whether the bonding strength between the edge-sealing strip and the hot sol is reasonable and uniform.

封边条的检测标准

Detection standard of edge sealing strip

01

Our edge banding products all have their professional testing standards in terms of their essential appearance and performance. Let's take a look at the testing standards for edge banding.

Appearance Quality

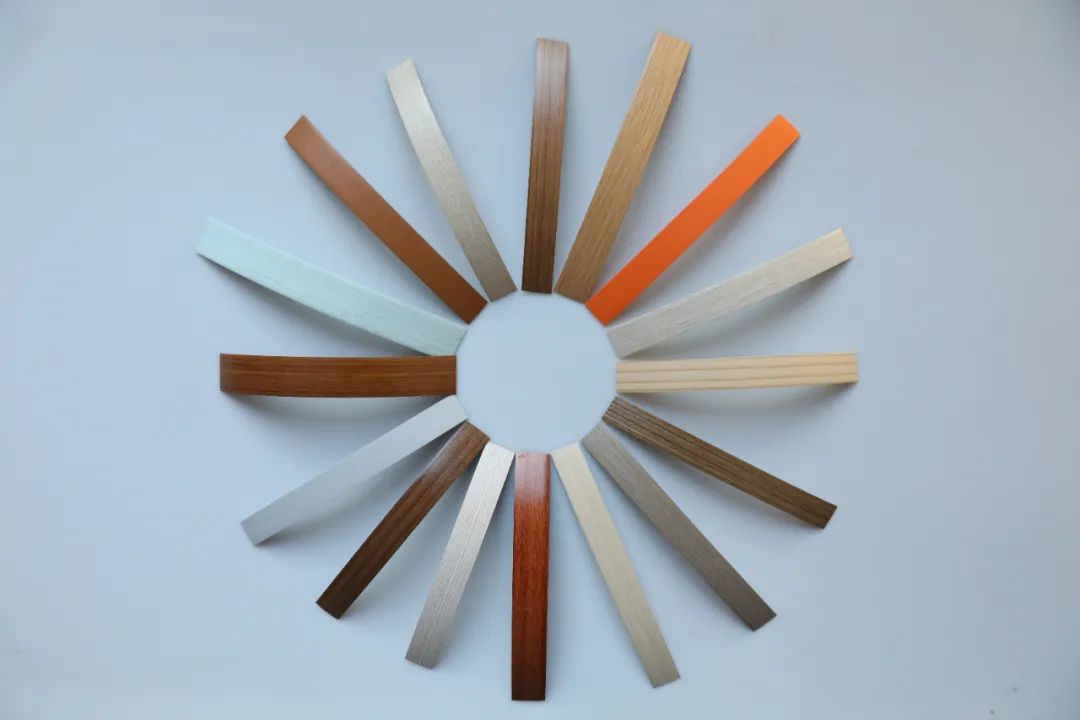

1. The color of each batch of edge strips is the same as the color of the main color sample, and the color requirements of the same batch of edge strips are the same.

2. When inspected under natural light, the surface of the edge banding strip should have no drawing lines, no blistering, no bumps, no scratches, no spots, no difference in lines, no bending marks, no stains, black spots, etc.

3. The surface is smooth and scratch-resistant, the printing texture is firmly attached, and there is no shedding phenomenon;

4. The hot melt adhesive on the back is firmly and evenly attached; there can be no more than two joints in the same edge band

physical dimension

Deviation requirements: width≤+0.2㎜, thickness≤+0.1㎜

The size of each batch of edge strips is required to be positive deviation, measured with a vernier caliper

Trial testing

The test machine has toughness, no bulging, corner drop, deformation phenomenon, and the test machine inspection is carried out according to the technical requirements

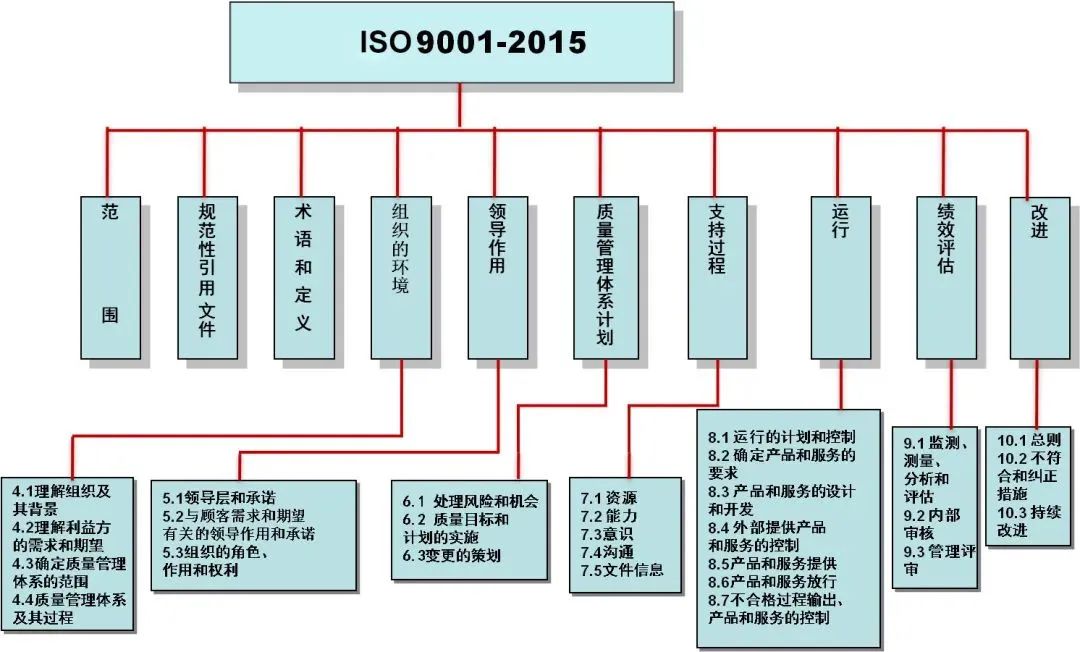

Because the edge sealing effect of furniture directly affects the quality of the furniture, and the quality of the edge banding directly affects the edge sealing effect. After more than ten years of experience, we have been focusing on the quality improvement of the edge banding industry. We always adhere to environmental protection and stability as the core competitiveness of our products, and strictly carry out quality control and high-quality safety guidelines to ensure that all our products meet the The strictest international standards.

The following is our test report

02

At the same time, the product ingredients all meet the environmental protection requirements of RHOS children's toys. Therefore, in terms of product quality, our Kemet materials must be your best choice!